KMA ULTRAVENT® air extraction and filtration systems

ULTRAVENT System Modules

ULTRAVENT systems - flexible and cost efficient

The ULTRAVENT® modules

The 6 module components for separating smoke, dust, mist and fumes at die casting machines, as well as recovering process heat for subsequent processes.

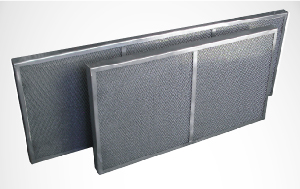

Demister

ULTRAVENT® demister units consist of robust 25 mm or 50 mm thick stainless steel mesh wire elements. This wire is held in position by expanded metal mesh, both on the incoming and outgoing side of the gas flow. The special shaping of the wire allows for a high separating capacity for aerosols, droplets and mist. The units can be washed for cleaning. Changing the demister elements is not necessary.

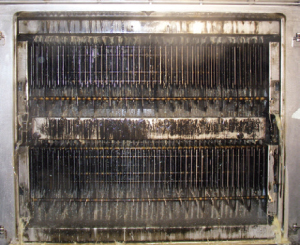

Electrostatic precipitator

ULTRAVENT® electrostatic filter cells assure the highly effective separation of smoke, dust and fine mist. The filter cells are characterised by the particularly robust design: frame, electrode and carrying bars made of stainless steel, collector plates optionally in aluminum or stainless steel, insulators in oil-resistant ceramics and an optimised design for the separation of liquid or viscous substances. These features make sure that the electrostatic filter is an economical and durable filter medium for many applications.

Often two categories of contaminants are captured in the electrostatic collection cell. One kind of the filtered substances is liquid, drips off the collection plates, and is collected in a recuperation tank. The oil separated here can often be reused. The second type forms a greasy, oily or encrusted deposit on the filter surface. Unsuitable filter types can quickly plug and become ineffective, leading to excessive costs associated with filter replacement and disposal. However, electrostatic precipitators never obstruct the air flow through the exhaust system.

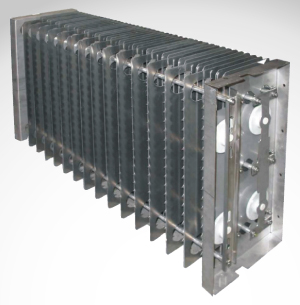

Heat exchanger

By integrating a heat exchanger in the ULTRAVENT® filter system a recovery of the process heat is made possible, in addition to the air purification. At low air temperatures, the heat recovery can be optimised by a combination with the highly efficient KMA Ambitherm® heat pump. The recovered heat from the exhaust air heat can be used afterwards for follow up processes (e. g. water or air heating). The immediate installation of the heat exchanger next to the filter zone allows regular cleaning by the automatic filter cleaning system.

Automatic filter cleaning system (CIP)

An automatic filter cleaning system is available for ULTRAVENT® emission control systems. It is suitable for cleaning all integrated filter media such as demisters, electrostatic collection cells or heat exchanger units. The automatic ULTRAVENT® washing system is unmatched interms of comfort and cleaning results - due to its movable nozzle bar that moves back and forth above the collection cells during the filter washing process. It allows the regular and labour-saving cleaning of the filter cells and thus ensures minimal maintenance requirements. The intelligent control of the washing system simultaneously reduces the consumption of water and of purifying agents.

Fire protection and fire extinguishing systems

ULTRAVENT® systems are widely used on machines which represent a certain fire hazard. All KMA systems are available with fire sensors and fire extinguishing systems as an option. In case of fire, the system ensures that the filter device will be flooded with an extinguishing gas. As a result, further damage to the equipment can be avoided.

PLC - programmable controllers

ULTRAVENT ® emission control systems are available with either contactor control or PLC. The PLC option is recommended when using the CIP cleaning device or in case of connection to a central monitoring system. Siemens S7 is used as the standard PLC at KMA. It lows the permanent monitoring and logging of all filter functions. It also enables the monitoring of connected media (e.g. electricity, if applicable: water or compressed air for filter cleaning). If the CIP cleaning system is part of the filter unit, the PLC allows for the convenient programming of cleaning time, temperature of washing water and more. In addition, the PLC allows the connection of the filter system to central control systems (BMS) and remote monitoring / service routines, which is an important aspect of ISO 14001 certification.